Steel corrosion protection methods

Protecting steel, preserving value: innovative steel corrosion solutions you can trust

Clients we´ve helped with our anti rust coating

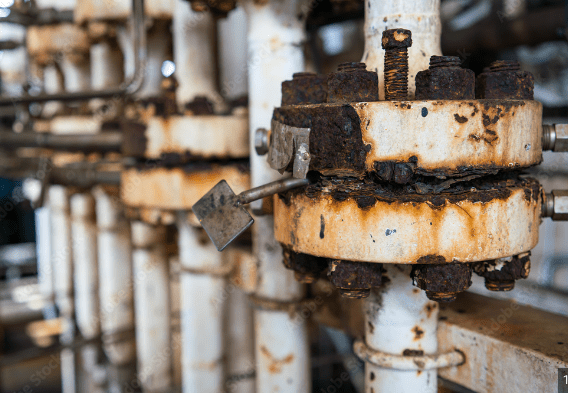

Why is steel corrosion prevention important?

Just like any other metal, there occurs corrosion when steel is exposed to the atmosphere. Metals can’t handle water and air, which is in the atmosphere. With as result, rust or the metals will turn green. The occurrence of corrosion is costly because it must be repaired.

Besides the fact that it is expensive, it is also very dangerous. If you want to store a spare part and keep it corrosion free, it is important to look for good steel protection coatings.

Anti corrosion methods & materials

The most common steel corrosion protection methods:

- Construct the structure in such a way that there is no change for even a little corrosion at all. Avoid narrow openings or holes and make sure that the construction is maintenance-friendly.

- Utilize materials that are the least susceptible to corrosion or that can withstand humidity.

- Use a coating to prevent rust on steel on the construction when it has to be stored for a longer period of time. This protective layer ensures that no air and humidity can enter the construction, so that the corrosion gets no change.

Learn more!

Request the free brochure and receive it directly into your e-mail inbox

Industries that benefit from corrosion protection

Offshore industry

Buildings / Real estate

Petrochemical energy

Anti corrosion coating for steel

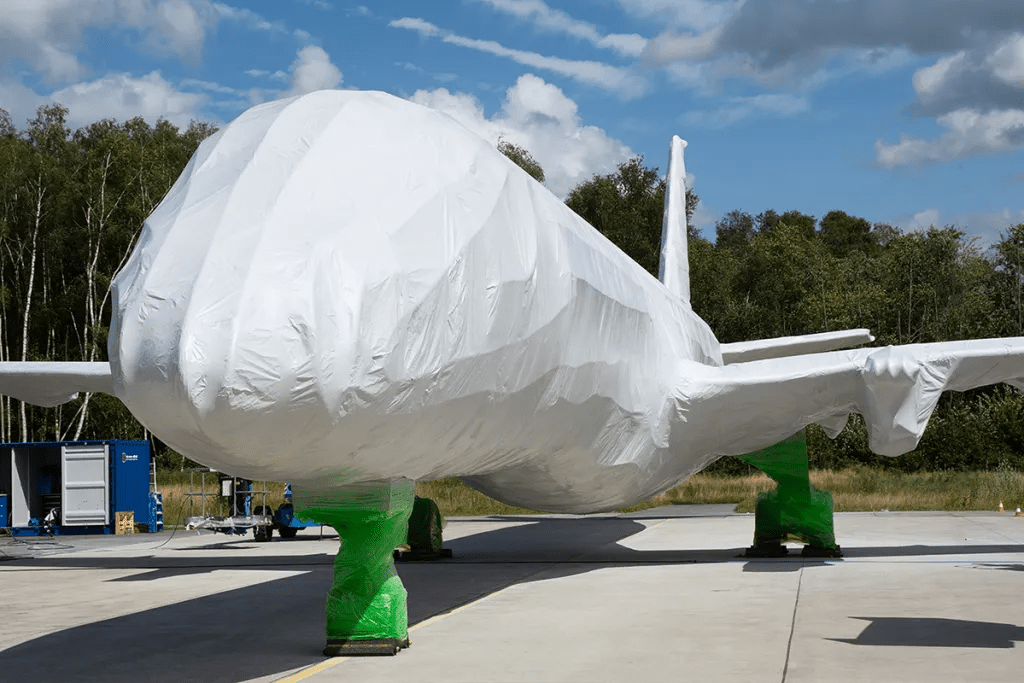

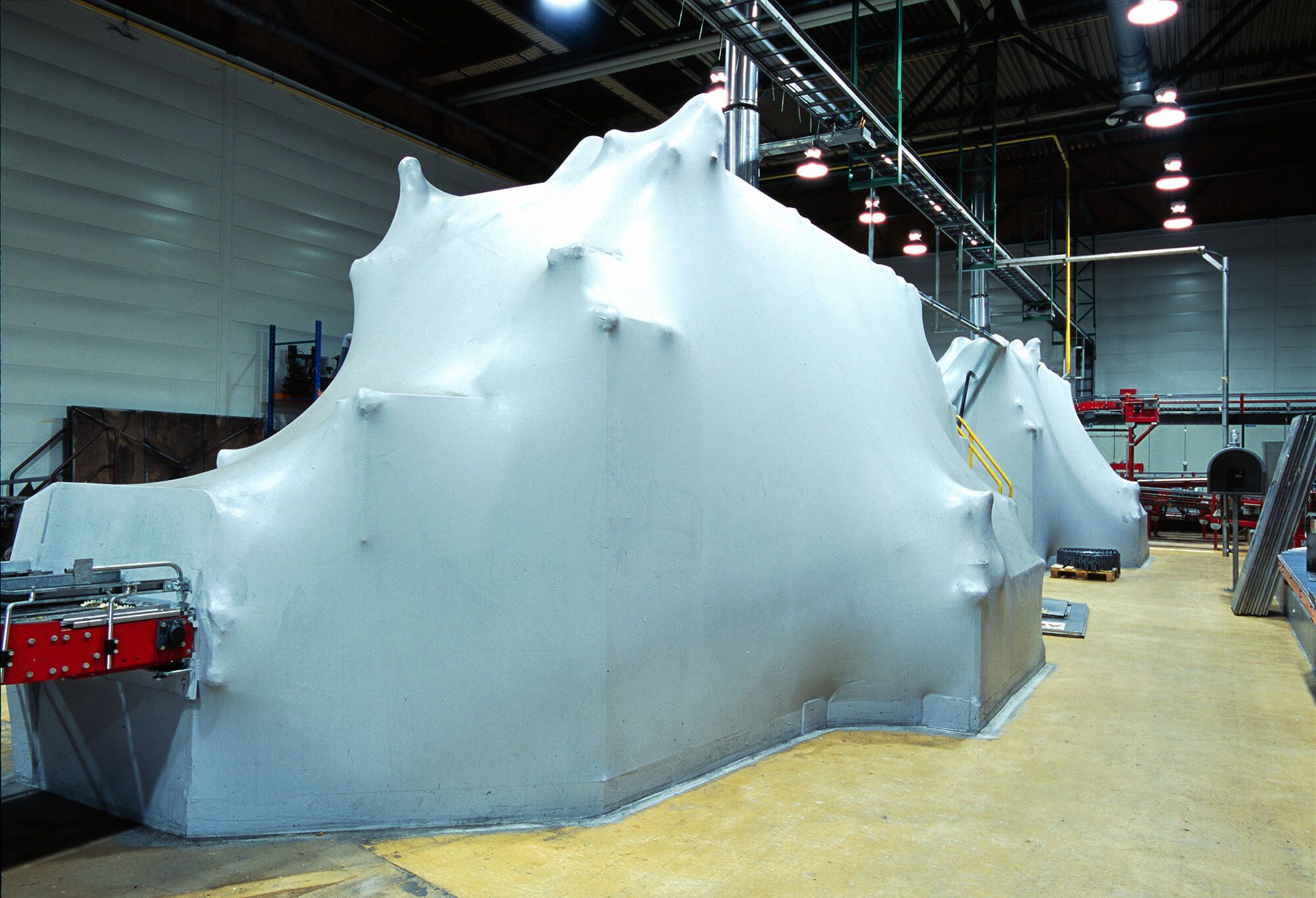

When you are in search of steel corrosion protection methods, you have various options to choose from. The most important thing is to look for a coating which ensures that the spare part you want to save, will remain the same quality. Cocoon Holland has years of experience in applying a coating to prevent corrosion. We call this our unique mothballing-method.

Our mothballing method is known worldwide and applied to many international projects. Our coating was developed over a century ago and has still not been surpassed. It is a high-quality, sprayable plastic which ensures that the structures remain corrosion-free for decades. Do you want to know what a construction looks like after thirty years of preservation through our mothballing system? Read this article.

Do you want to know more about our anti corrosion coating for steel?

Please share your current challenges to see if we can help you.

Anti corrosion coating for multiple industries

How our anti rust coating ensures long-lasting results

Cocoon is a versatile and durable protective material with a range of unique characteristics that make it ideal for various industrial and environmental applications. It can be applied to nearly all construction materials, offering exceptional adhesion and flexibility, including elasticity and expansion joints where needed.

Its weather-resistant properties, such as high UV resistance and tensile strength, ensure long-lasting protection even in harsh conditions, including wind, extreme temperatures (-42°C to +85°C), and exposure to seawater, sandstorms, and air pollution. Cocoon is also seam-free, pore-free, and available in any desired colour except metallic, with excellent colour fastness over time.

Characteristics of our anti corrosion coating for steel, metal and more

Its technical properties are equally impressive: Cocoon can stretch up to 2.5 times its original size and return to its form, maintain high electrical resistance, and resist fire, flash fires, and low smoke emission. Additionally, it is resistant to bacteria, alkalis, oils, industrial acids, and alcohol, making it suitable for the most demanding environments.

Cocoon also bonds seamlessly with older layers, enabling repairs or extensions to systems already in use for over a decade.

With a virtually zero water vapour transmission rate and a fungicidal composition, Cocoon delivers unmatched durability, reliability, and protection, ensuring a long lifespan and superior performance in protecting valuable assets.

Download our brochure

Do you want more information about our projects?

Download our brochure via the button underneath. It will link you direct to the information you need about our products and services.

(no contact info needed!)