Project summary

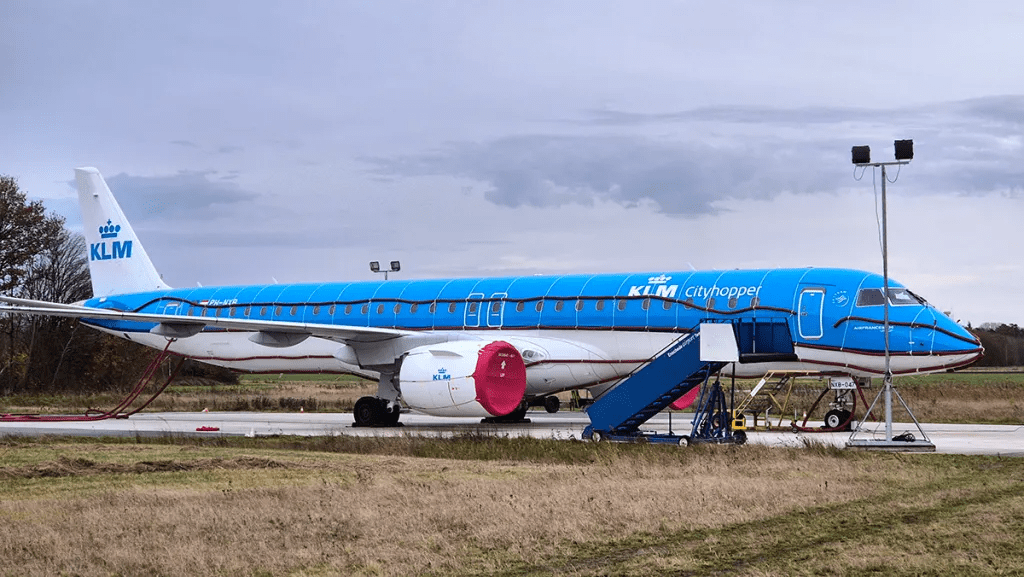

Packing a plane for two, three months, you don’t. From the beginning, we said that these Embraers will be packed for two, maybe even two-and-a-half, three years. When urgently needed, we will unpack these airplanes within a few days.

Location

Twente Airport

Client

Realisation

Technique

Product

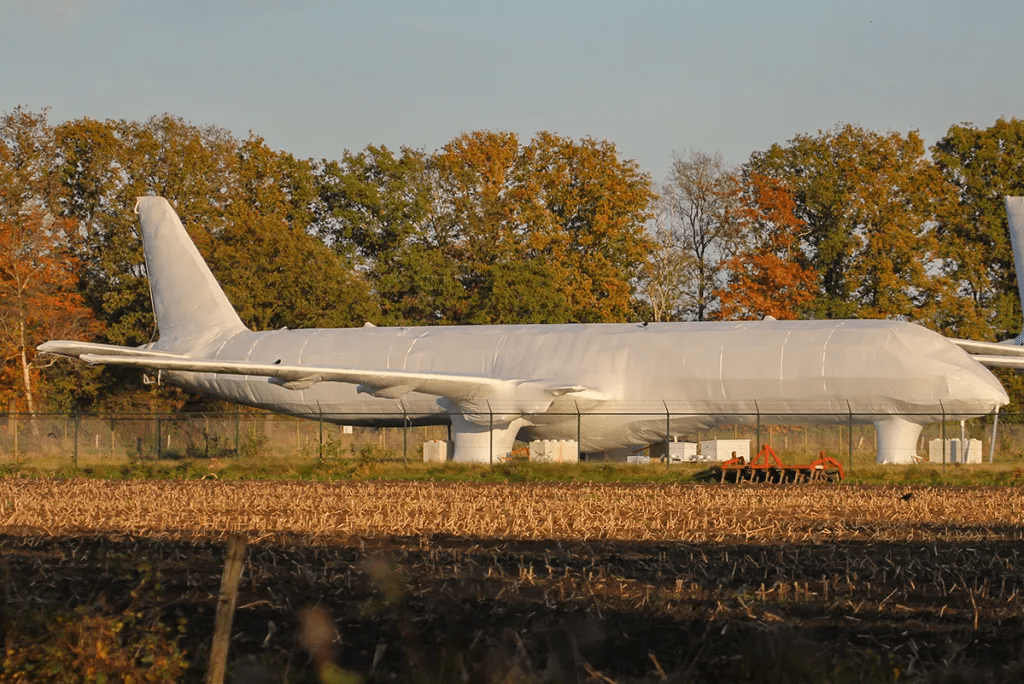

*Slide the element in the centre from left to right for a before & after

With this approach, we are the first to come up with a time machine. We can stop time, maintenance time, which is, after all, stopped for these E2s that are now cocooned.

Jeroen van Eijk

Project Manager Fleet renewal, KLM Cityhopper

Results

Packing one Embraer 195-E2 airplane took us 6 weeks

Inside our mothballing system is a conditioned climate that controls humidity and keeps it stable at around 38%

Rust, mould and dehydration of rubbers and plastics are thus eliminated

What did we do?

Mothballing an airplane. What did we do?

KLM Cityhopper chose to park a number of young Embraers due to engine maintenance at the 195-E2 to park at Twente Airport for the time being.

What we did

We packed two Embraers aircraft with our mothballing system. A system that allows the precious equipment to be mothballed, so to speak. This system creates a hermetically sealed plastic cocoon around the equipment. Inside that plastic skin is a conditioned climate that controls humidity and keeps it stable at around 38%. Rust, mould and dehydration of rubbers and plastics are thus eliminated. There is ozone in everything. The system also removes ozone from the air.

Situation

As soon as the engines are off a machine, that machine is off. You don’t do anything with it anymore and that’s not good for an aircraft. Normally you do an engine swap and the aircraft can go back into operations with a few days. When it became clear that the engines of these 18 E2s had to go to the shop, they knew they would go through the spare stock at some point.

Challenges

- Twente Airport is not part of KLM Cityhopper’s destinations. A flight plan had to be made with VFR and the turning point to be made on approach also posed a separate challenge.

- For each aircraft, the undercarriage was put in an aluminium container because you have to connect somewhere airtight. Moreover, you don’t want moisture from the concrete base to get into the aircraft.

- Both the deflated tyres and the aluminium container were packed. This makes them part of the Cocoon Mothballing System.’

Frequently asked questions about this KLM project

How does the anti-corrosion system work?

The system uses air dryers that circulate dry, unheated air throughout the aircraft. It keeps humidity levels consistently low, preventing rust. The equipment is modular, energy-efficient, and requires minimal human intervention.

Does it need power for the data monitoring system?

We offer two options; for one system a powersupply is necessary and for the other we have what we call a “stand alone system” which doesn’t require power and batterie life-span is +1,5 to 2 years. Mainly set on intervals every 10mins and gives an exact reading of temp & RH.

What about mold from moisture inside the cabin?

No corrosion can occur in the cabin itself. Everything is connected to the air dryer. Cabin is connected to the unit’s internal air conditioner.

Were the aircraft engines removed?

Yes. When aircraft is parked for longer period engines are preserved,removed and stored. The engines were removed and sent to the manufacturer for updates. The aircraft had to remain in excellent condition without their engines, making controlled environmental storage even more critical.

How do you manage the periodic storage checks and general parking/storage maintenance program in such of airframe preservation?

We have made access to the aircraft possible by mounting a ‘zipperdoor’ in the Cocoon at the entrance door. Which means, inspection and checks are possible at any time. We maintain the RH at approx. 38% and monitor this and temperature 24/7 hooked up to an automatic alarm system if an error or malfunction should occur.

What makes this solution innovative?

Unlike traditional storage solutions, Cocoon Holland’s approach uses smart, plug-and-play systems that are scalable, energy-efficient, and capable of maintaining safe conditions for months or years. This method is low-impact, cost-effective, and preserves operational readiness.

Do you flush the cabin with nitrogen?

No, we olny bring the desired RH to the desired level and take out the ozone.

Could we refer to this as pickling?

No. Mothballing and pickling both refer to preservation methods, but they apply in different contexts and have different purposes. What we implement is a mothballing system. The goal is to preserve equipment or systems for longterm storage so they can be reactivated later with minimal effort and cost. Pickling involves soaking the metal in a solution of acid. That is not what we do.

Wouldn´t it be cheaper just to build a climate controlled building for the airplane?

An airtight hangar is also a possibility. 4 completely airtight hangars wouldn´t have been cheaper for these aircraft. In this case, the customer opted for this solution.

Would you like to discuss the possibilities?

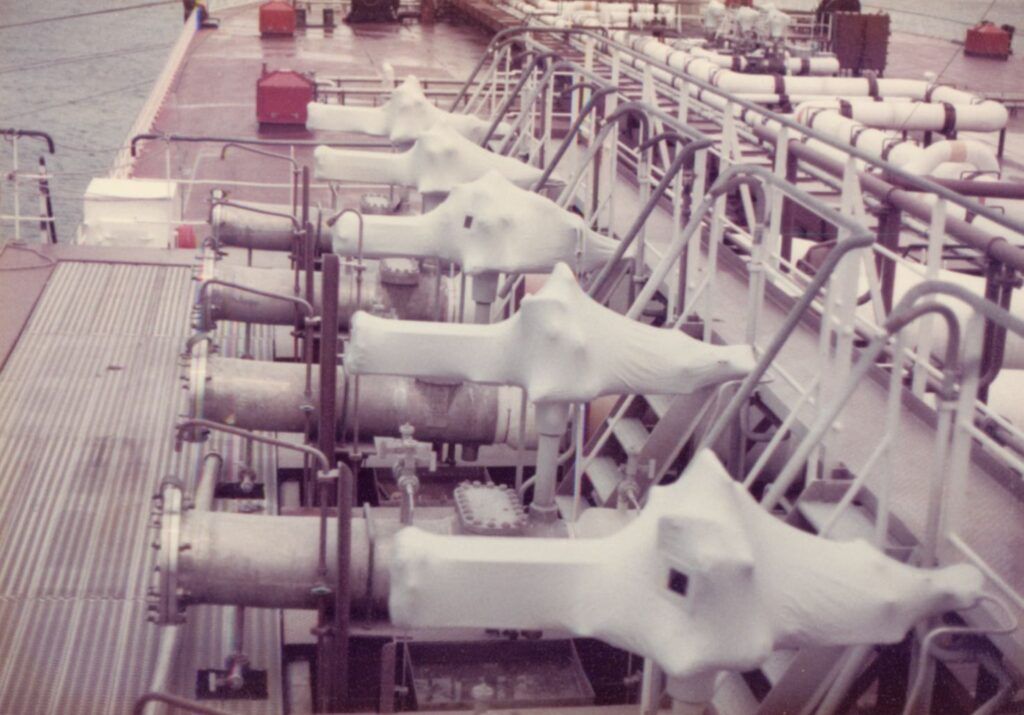

Other mothballing projects

Other customers we´ve helped with our mothballing solution