The offshore and renewable energy sectors are critical to global energy production, but they come with unique challenges, especially in accessing and maintaining infrastructure.

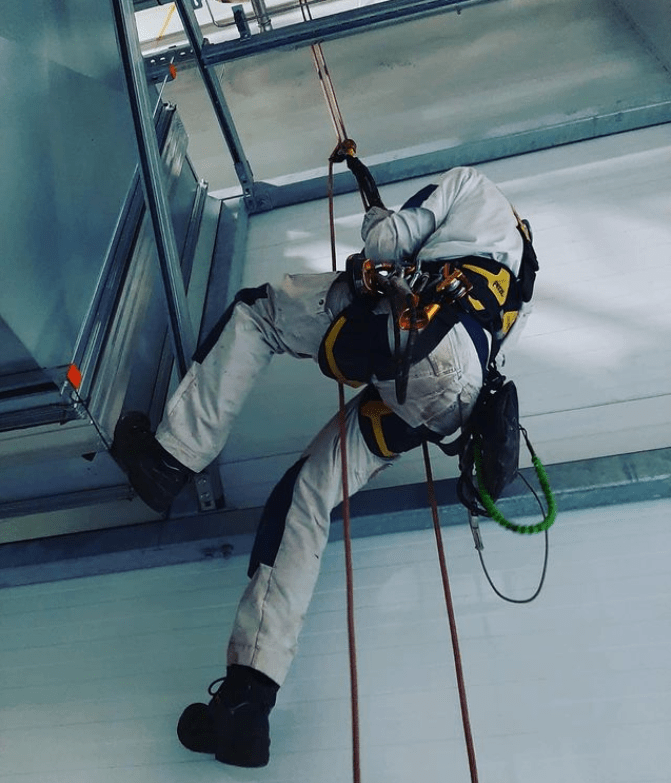

Rope access, a proven method for working at height, has revolutionised how these sectors handle inspections, repairs, and maintenance.

This article explores the applications of rope access in wind turbine maintenance, oil rig inspections, and other offshore tasks, highlighting its efficiency, cost-effectiveness, and safety benefits.

Why rope access in offshore and renewable energy?

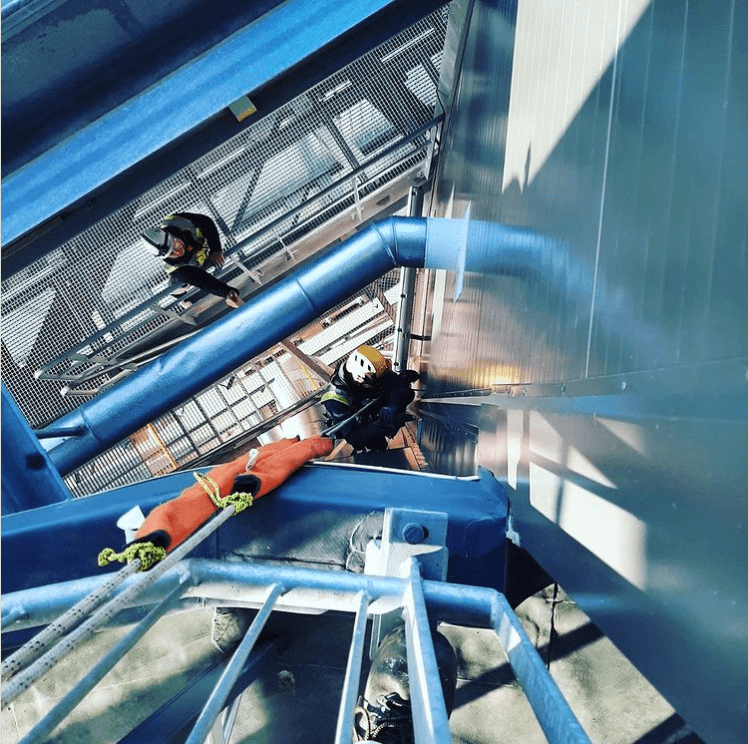

Offshore and renewable energy environments are characterised by tall, hard-to-reach structures and exposure to extreme weather conditions.

Traditional access methods like scaffolding or aerial lifts are often impractical or expensive in such settings. Rope access offers a streamlined alternative, allowing technicians to reach challenging areas quickly and safely.

By relying on ropes and harnesses instead of bulky equipment, rope access minimises setup time and costs while providing unparalleled versatility.

Applications in wind turbine maintenance

Inspections:

Wind turbines are typically located in remote areas, either onshore or offshore, making regular inspections essential for maintaining efficiency and preventing costly breakdowns.

Rope access technicians perform detailed inspections of turbine blades, nacelles, and towers, identifying issues like cracks, erosion, and lightning damage. The flexibility of rope access enables technicians to move seamlessly across the structure, covering large areas with precision.

Repairs:

When issues are detected, rope access is often the fastest way to implement repairs. Technicians can perform tasks such as blade patching, leading-edge protection, and structural reinforcement without the need for crane deployment.

This reduces downtime and ensures that turbines return to optimal operation as quickly as possible.

Cleaning and maintenance:

Accumulation of dirt, salt, and other debris on turbine blades can reduce efficiency.

Rope access technicians are skilled in cleaning turbine components, applying protective coatings, and carrying out regular maintenance to maximise energy output.

Oil Rig inspections and maintenance

Structural inspections:

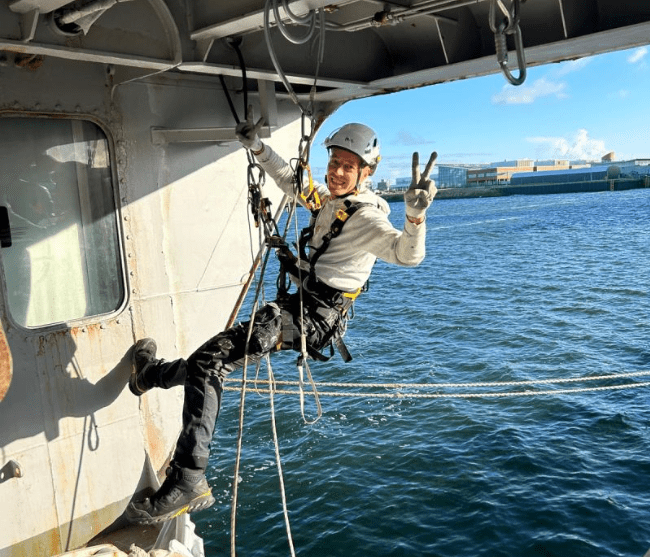

Oil rigs operate in harsh marine environments, where structural integrity is constantly tested by saltwater corrosion and extreme weather. Rope access is used to inspect every aspect of a rig, from its underwater foundations to its uppermost platforms.

Non-destructive testing (NDT) methods, such as ultrasonic or magnetic particle testing, can be performed while suspended, ensuring safety and precision.

Repairs and welding:

For damaged structures or components, rope access technicians are trained to conduct repairs and even perform welding tasks at height. This eliminates the need for complex scaffolding systems and significantly reduces downtime.

Cleaning and coating:

Saltwater exposure accelerates rust and corrosion on oil rigs, making regular cleaning and coating applications essential. Rope access allows technicians to apply anti-corrosion coatings or clean surfaces efficiently, even in confined or difficult-to-reach areas.

Other offshore applications

-

Pipeline inspections: Rope access is ideal for inspecting pipelines, both above and below water, ensuring the integrity of crucial oil and gas transportation systems.

-

Platform decommissioning: When platforms reach the end of their operational life, rope access is a practical method for dismantling and removing structures safely.

-

Emergency response: In emergencies, such as equipment failures or structural damage caused by storms, rope access teams can quickly mobilise to assess and address issues.

Benefits of rope access in these sectors

-

Cost-effectiveness: Rope access eliminates the need for heavy machinery, reducing setup and operational costs.

-

Efficiency: Technicians can quickly access problem areas without the delays associated with scaffolding or crane installations.

-

Safety: Certified rope access technicians adhere to stringent safety standards, ensuring minimal risk during operations.

-

Environmental impact: With minimal equipment and a small operational footprint, rope access is a sustainable choice for offshore and renewable energy tasks.

Want to know more about this subject?

Read more about it via the articles underneath:

- Rope access Irata level 1 specialist.

- Rope access Irata level 2 specialist.

- Rope access Irata level 3 specialist.

- Industries that benefit most from rope access.

Contact us today if you´re looking for a rope access solution.

T: +31 (0)20 6867 808

Alexander van der Zee, owner Cocoon Holland B.V.